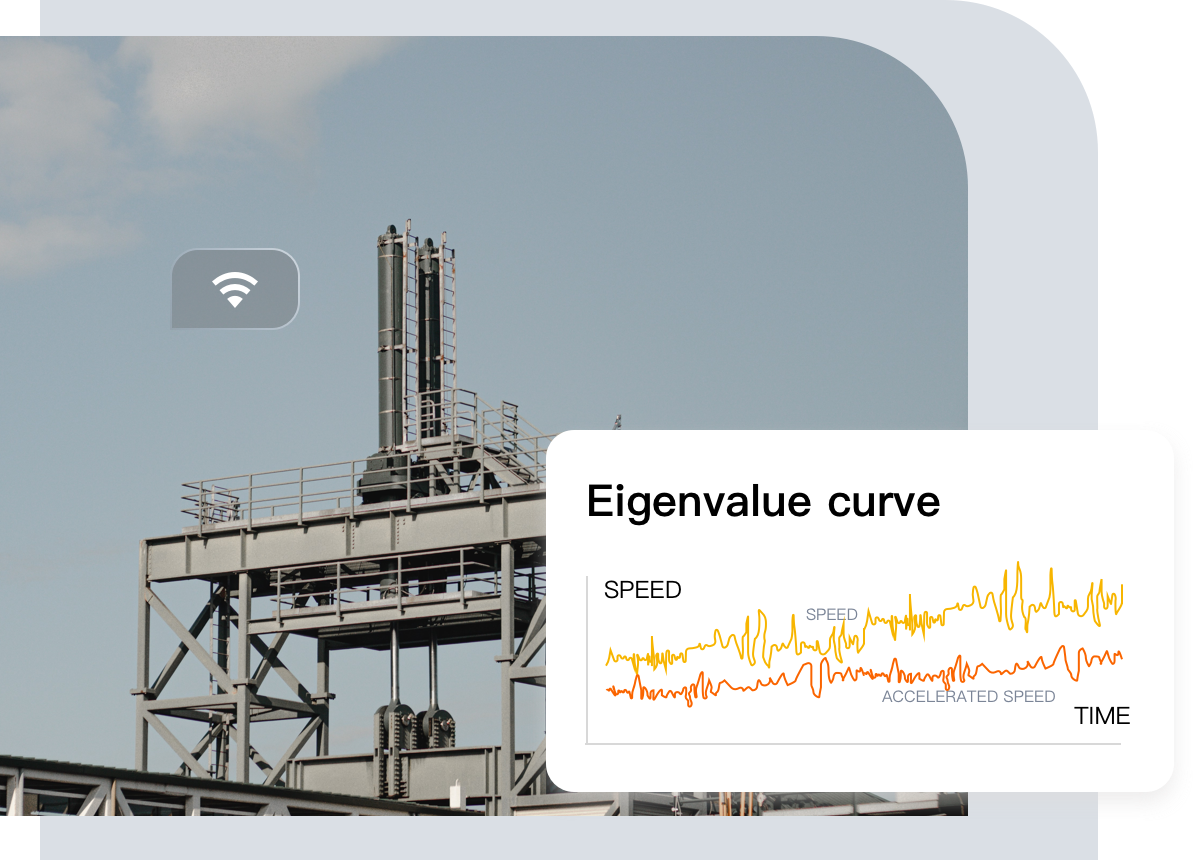

ZETA Industrial SaaS Platform

The "Talking Machine Assistant"

Monitoring 24/7 | AI-powered Monitoring | High-Precision Data Collection

Intelligent Alerts | Predictive Maintenance | Adaptive Thresholds

ZETA's Smart Sensors provide real-time monitoring of industrial equipment conditions such as vibration and pressure. With built-in smart algorithms, these terminals autonomously learn and employ adaptive threshold algorithms for diagnostics. They extract crucial features and synchronize data to the SaaS cloud platform. In comparison to ISO standards, they can offer advance warning for equipment anomalies by 7 days to 3 months, enabling predictive maintenance and ensuring safe and stable production. This technology empowers factories to achieve intelligent management.